At GCER, we specialise in the manufacture of a wide range of GRP (glass-reinforced plastic) tanks, suitable for a variety of industrial applications.

Our GRP tanks are designed for the safe storage of liquid fluids, meeting the highest standards of quality and durability.

Each GRP tank is precision-manufactured using top-quality materials and advanced production techniques. We are committed to providing storage solutions that combine robustness, chemical resistance, and longevity. Our tanks are available in a variety of configurations to suit all storage needs, ensuring optimum performance and easy maintenance.

Advanced manufacturing methods for GRP tanks are based on :

this involves winding the material in wire or strip form around a reference mandrel.

A simple process for creating composite products, enabling a wide variety of shapes to be produced with optimum surface finish.

An advanced technique used to reinforce the structure of tanks, improving their strength and durability.

Vertical tanks are essential for the efficient storage of liquids in various sectors. Designed to optimize space utilization and offer high stability, these tanks are available in several configurations to meet the specific needs of each application. https://gcertunisie.comWhether storing food, chemical or industrial products, vertical tanks offer robust, cost-effective solutions, manufactured in SVR-GRP or SVR-GRP with a thermoplastic liner, in compliance with the most stringent international standards.

Here are our different ranges of vertical tanks to suit your requirements :

Vertical GRP tanks on skirt are made of GRP or GRP with a thermoplastic liner. They are dimensioned in accordance with EN 13121-3 or other worldwide standards.

These GRP tanks are typically fitted with domed upper and lower bottoms, providing an even distribution of stresses. However, configurations with flat or conical bottoms are also available, depending on specific project requirements.

The standard capacities of these tanks range from 1 to 150 m³, with diameters from 1000 mm to 4000 mm, suitable for a wide range of applications.

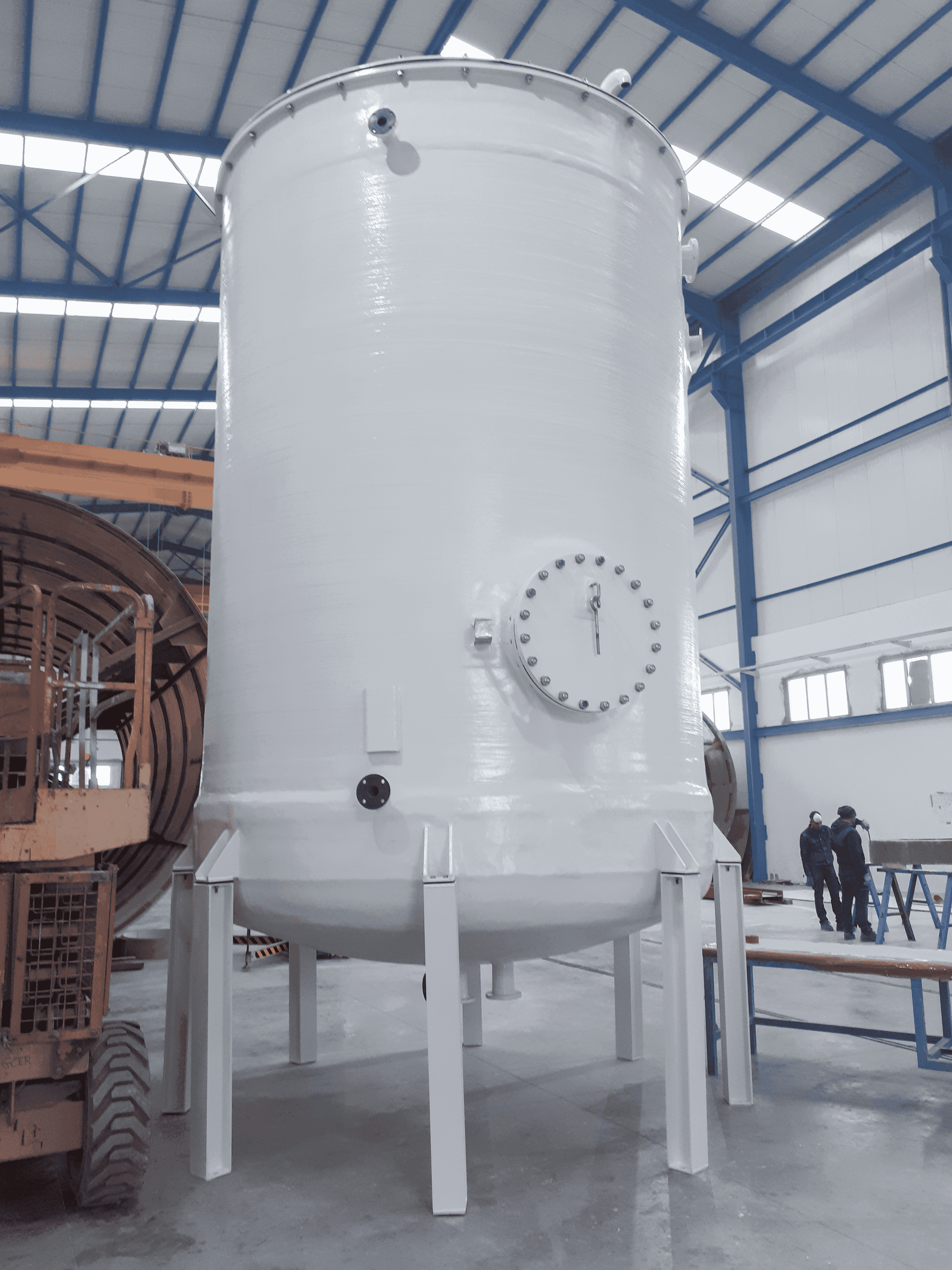

Vertical GRP tanks with legs are specially designed for the storage of food or industrial products, meeting strict requirements in terms of cleanliness and impurity management. They can be emptied completely at regular intervals, facilitating thorough cleaning after each use.

Constructed in GRP or GRP with a thermoplastic liner, these tanks are sized in accordance with European standard EN 13121-3 or various worldwide standards.

Tanks are generally fitted with domed top and bottom for uniform load distribution, although flat top configurations are also available to meet specific requirements.

Standard tank capacities range from 1 m³ to 60 m³, with standard diameters from 1000 mm to 3000 mm. Customised configurations with smaller diameters can also be made on request.

Vertical GRP tanks with flat bottom are a preferred solution for overhead storage facilities because of their low cost and ease of installation directly on a concrete slab, without the need for additional operations.

Constructed from GRP or GRP with a thermoplastic liner, these tanks are sized in accordance with European standard EN 13121-3 or other rigorous international standards such as BS 4994, ASTM D-3299, ASTM D-4097, AD 2000 Merkblatt-N1, NF T57-900, ASMEX and ASME RTP-1.

Typically, these tanks are fitted with a GRC or PRC roof, although specific configurations such as a sloping flat bottom, a flat or partial roof, a conical roof, or even no roof, can be produced depending on project requirements.

The ferrule is manufactured using the filament winding process, while the bottom and fittings are made by contact or spray moulding.

Standard tanks range in size from 1 to 200 m³, with larger capacities available on request. The maximum diameter is ∅ 6000 mm.

Horizontal tanks are the preferred solution for surface installations faced with height restrictions imposed by town planning regulations, visual constraints and available space.

GCER offers a wide range of horizontal tanks in GRP or GRP with thermoplastic liner, these tanks can take the following forms :

Our tanks are designed in accordance with European standard EN 13121-3 or other internationally recognised standards. We can produce tanks with a maximum diameter of up to ∅ 6000mm, but we can also manufacture tanks with smaller diameters on specific request.

Underground tanks are the ideal solution for above-ground storage facilities, offer low cost and can be installed directly on a concrete slab, without any additional operations.

These vertical, flat bottom tanks are made of GRP or GRP with a thermoplastic liner, ensuring optimum resistance to environmental conditions and long durability.

Double wall tanks are specially designed for the safe storage of potentially dangerous liquids, offering enhanced protection against leaks and environmental incidents.

They come in two main configurations :

Each tank is equipped with a leak detection device to ensure constant monitoring of fluids and rapid response in the event of a problem.

Rectangular tanks are essential in industrial projects for specific applications, including the treatment and storage of various fluids.

Their rectangular design allows optimum use of space and precise adaptation to the particular requirements of industrial installations.

Road tanks are specially designed for transporting chemical and food products by road.

The main features of a transport tank are :

Transport tank capacities range from 1 m³ to 25 m³, suitable for a wide range of applications.

GRP (Glass Reinforced Polyester) is a composite material combining polyester resin and glass fibers. This combination gives it high mechanical strength, excellent durability, and remarkable chemical resistance.

GRP (Glass Reinforced Polyester) is a composite material offering an exceptional combination of lightness, mechanical strength, and durability. It is distinguished by its high resistance to corrosion, chemicals, and extreme environmental conditions, making it ideal for a wide range of industrial applications. In addition, its design flexibility allows for the manufacture of custom structures, optimizing the performance and longevity of equipment.

GRP (Glass Reinforced Polyester) cannot be recycled in the same way as traditional plastics. Due to its composite composition—a polymer matrix reinforced with glass fibers—conventional mechanical recycling is difficult. However, there are specialized processes for recovering end-of-life materials, including energy recovery or grinding techniques and reuse in secondary applications (fillers, construction materials, etc.). In addition, research is underway to develop more sustainable recycling methods for composites. GCER remains attentive to these technological developments in order to integrate environmentally friendly solutions into its processes.

Yes, we specialize in custom design. Our engineers work collaboratively with our customers to develop solutions tailored to their requirements.

GCER is located in Ksibet Sousse, Tunisia, specifically on Route de Thrayet. For any information requests, you can contact us : By phone: +216 73 238 960 / +216 70 015 590 By email: commercial@gcertunisie.tn Or directly via our online contact form: https://gcertunisie.com/demande-de-contact

To obtain a quote, please fill out the quote request form on our website or contact our sales team directly by email at the following address : commercial@gcertunisie.tn We will respond as soon as possible.

GCER is certified: ✅ ISO 9001:2015 – Quality management systems ✅ ISO 14001:2015 – Environmental management systems ✅ ISO 45001:2018 – Occupational health and safety management systems ✅ MSI (Materials, Systems, Installations) – Technical certification guaranteeing the compliance of products and processes with specific sector requirements ✅ Authorized Economic Operator (AEO) – Customs recognition attesting to the reliability of the company in the international supply chain These certifications demonstrate GCER's commitment to quality, safety, regulatory compliance, and customer satisfaction, while ensuring reliable, sustainable, and certified solutions.

GRP (Glass Reinforced Polyester) equipment has a service life of between 30 and 50 years, depending on conditions of use and maintenance. Its resistance to corrosion and low maintenance requirements ensure a long service life. Regular maintenance helps to preserve its performance and maximize its service life.

We use several GRP manufacturing technologies, including filament winding, contact molding, and simultaneous projection, to ensure that our equipment is durable and complies with the most stringent international standards.

Yes, we offer an assembly service for all our equipment. Our technical team ensures that assembly complies with standards, guaranteeing optimal installation and reliable operation of your products.

Manufacturing and delivery times depend on the project. We are committed to providing you with fast solutions tailored to our customers' needs.

At GCER, the manufacturing process involves several steps : 1. Research and design : We begin by studying each customer's specific needs in order to design tailored solutions. 2. Manufacturing : The equipment is manufactured in our workshops. 3. Quality control : We check the compliance of each piece of equipment during manufacturing. 4. Testing : Each piece of equipment is tested before delivery. 5. Delivery : The equipment is delivered to the project site on schedule. 6. On-site installation : Our teams install the equipment on site quickly and efficiently.

At GCER, we offer comprehensive solutions for your industrial projects, taking care of every step from design to commissioning. With us, you benefit from a single partner who ensures optimal coordination, on-time delivery, and consistent quality. Our solutions are tailored to your specific needs, backed by our expertise and rigorous monitoring. Contact us today for your industrial projects.

GCER operates in various sectors, including : • Water and water desalination • Wastewater • Chemicals • Agri-food • Energy • Mining • Oil • Environment • Industrial processes

GCER specializes in : • Composite materials (GRP) • Thermoplastics such as HDPE, PVC, PPH, PVDF, PVC-C, ECTFE, and PFA • Metal construction

To find out if thermoplastic or GRP equipment has reached the end of its service life, check for : • Cracks or deformations. • Loss of resistance to stress. • Leaks or damaged seals. • Reduced performance after testing or inspections. It is important to follow the manufacturer's recommendations and carry out regular checks.

GRP (Glass Reinforced Polyester) is generally more expensive than thermoplastics. This difference is due to a more complex manufacturing process and the use of reinforced materials. However, GRP offers better mechanical and chemical resistance, making it ideal for demanding applications.

The lifespan of a GRP (Glass Reinforced Polyester) tank is generally longer than that of a steel tank. • GRP tank : it can last between 30 and 50 years, or even longer, as it does not rust and is resistant to chemicals and harsh conditions. It is also lightweight during installation and can be buried or above ground, reducing maintenance and handling costs. • Steel tank : its lifespan is often 15 to 25 years, as it can rust and corrode, especially if exposed to moisture or chemicals.

GRP (Glass Reinforced Polyester) tanks are more expensive than steel tanks because they are made from more costly materials, such as resins and glass fibers. In addition, their manufacture is more complex. However, they last longer, are more resistant to corrosion, and require less maintenance.

GRP (Glass Reinforced Polyester) tanks are used to store a wide range of liquids, including drinking water, rainwater, chemicals, industrial liquids, and food products, etc. Their resistance to corrosion and chemicals makes them suitable for these applications.

GRP (Glass Reinforced Polyester) tanks are manufactured by combining resins and glass fibers, which gives them high resistance to corrosion, chemicals, and heat. Thermoplastic tanks, on the other hand, are made from plastics such as PVC, HDPE, or PP, etc. These plastics are more flexible and easier to mold. Thermoplastic tanks are often lighter, but GRP tanks offer better mechanical strength and are more suitable for extreme conditions.

GRP tanks generally have a longer service life than thermoplastic tanks due to their increased resistance to corrosion, chemicals, and extreme conditions. A GRP tank can last between 30 and 50 years, while a thermoplastic tank can have a lifespan of 15 to 25 years, depending on the conditions of use and the type of liquid stored.

GRP tanks are suitable for storing a wide range of liquids, including aggressive chemicals, oils, acids, and bases. Thermoplastic tanks are better suited to less aggressive liquids, but certain materials such as HDPE or PVC can be used to store specific chemicals. It is important to ensure that the tank material is compatible with the liquid to be stored in order to prevent degradation of the tank.