At GCER, we believe that a successful industrial project relies on an integrated and consistent approach. Our motto, “Why deal with multiple suppliers when you can carry out your industrial project with a single provider,” reflects our commitment to providing comprehensive and optimized solutions. Thanks to our dedicated metal construction department, we ensure the autonomy of our GRP piping and boiler making production.

Metal construction at GCER is more than just the fabrication of steel structures. We take a holistic approach that encompasses every stage from concept to completion, ensuring a finished product that meets the highest quality standards. Our metal construction team works closely with our piping and boilermaking teams, ensuring perfect synergy and optimum coordination.

The harmonious integration of metal construction with SVR/GRP piping and boilermaking offers a number of advantages.

By integrating metal construction with SVR / GRP piping and boilermaking, we ensure consistent quality throughout the production chain. Each component is designed and manufactured with the specific requirements of the project in mind, reducing the risks of incompatibility and non-conformity.

The collaboration between our teams enables us to respect delivery deadlines. This internal synchronisation eliminates the delays often caused by multiple subcontractors, and ensures that projects are carried out quickly and efficiently.

By bypassing subcontractors and manufacturing the steelwork ourselves, we are able to offer competitive prices. This integration allows us to control costs at every stage, offering greater added value to our customers.

Our metal construction department is equipped with state-of-the-art technology and managed by highly qualified professionals. This dedicated team is capable of designing, fabricating and erecting complex steel structures to the highest international standards.

GCER offers a complete range of services :

Conception and Engineering

Our engineers work closely with customers to design tailor-made solutions that meet their specific needs. Each project begins with a detailed analysis and rigorous planning, ensuring the feasibility and effectiveness of the proposed solution.

Manufacturing

Using modern equipment and advanced techniques, our manufacturing team produces high-quality metal structures. Precision and attention to detail are essential to ensure the durability and performance of our products.

Assembly and Installation

Our assembly teams are trained to install metal structures quickly and safely. They work in coordination with other departments to ensure that the various components of the project are seamlessly integrated.

At GCER, we continually invest in innovation and cutting-edge technology to improve our manufacturing and construction processes. This includes the use of computer-aided design (CAD) software to create accurate 3D models, as well as the integration of advanced manufacturing techniques such as laser cutting.

Sustainability and safety are top priorities at GCER. We are committed to responsible construction practices and environmental standards. Our steel structures are designed to be robust and durable, minimising environmental impact over the long term.

GCER demonstrates its commitment to sustainability by integrating environmentally friendly practices throughout the manufacturing process.

Use of Recyclable Materials

We favour the use of recyclable materials in the manufacture of our metal structures, thus contributing to the reduction of waste and the preservation of natural resources.

Energy efficiency

Our manufacturing processes are optimised to reduce energy consumption, and we use energy-efficient equipment to minimise our carbon footprint.

GCER ensures a safe working environment through :

Training and Awareness

Our teams receive regular training on safety practices and protocols to ensure a safe and healthy working environment.

Compliance with Norms

We strictly adhere to national and international safety norms, and implement rigorous measures to prevent accidents and incidents on our construction sites.

Yes, we specialize in custom design. Our engineers work collaboratively with our customers to develop solutions tailored to their requirements.

GCER is located in Ksibet Sousse, Tunisia, specifically on Route de Thrayet. For any information requests, you can contact us : By phone: +216 73 238 960 / +216 70 015 590 By email: commercial@gcertunisie.tn Or directly via our online contact form: https://gcertunisie.com/demande-de-contact

To obtain a quote, please fill out the quote request form on our website or contact our sales team directly by email at the following address : commercial@gcertunisie.tn We will respond as soon as possible.

GCER is certified: ✅ ISO 9001:2015 – Quality management systems ✅ ISO 14001:2015 – Environmental management systems ✅ ISO 45001:2018 – Occupational health and safety management systems ✅ MSI (Materials, Systems, Installations) – Technical certification guaranteeing the compliance of products and processes with specific sector requirements ✅ Authorized Economic Operator (AEO) – Customs recognition attesting to the reliability of the company in the international supply chain These certifications demonstrate GCER's commitment to quality, safety, regulatory compliance, and customer satisfaction, while ensuring reliable, sustainable, and certified solutions.

Yes, we offer an assembly service for all our equipment. Our technical team ensures that assembly complies with standards, guaranteeing optimal installation and reliable operation of your products.

Manufacturing and delivery times depend on the project. We are committed to providing you with fast solutions tailored to our customers' needs.

At GCER, the manufacturing process involves several steps : 1. Research and design : We begin by studying each customer's specific needs in order to design tailored solutions. 2. Manufacturing : The equipment is manufactured in our workshops. 3. Quality control : We check the compliance of each piece of equipment during manufacturing. 4. Testing : Each piece of equipment is tested before delivery. 5. Delivery : The equipment is delivered to the project site on schedule. 6. On-site installation : Our teams install the equipment on site quickly and efficiently.

At GCER, we offer comprehensive solutions for your industrial projects, taking care of every step from design to commissioning. With us, you benefit from a single partner who ensures optimal coordination, on-time delivery, and consistent quality. Our solutions are tailored to your specific needs, backed by our expertise and rigorous monitoring. Contact us today for your industrial projects.

GCER operates in various sectors, including : • Water and water desalination • Wastewater • Chemicals • Agri-food • Energy • Mining • Oil • Environment • Industrial processes

GCER specializes in : • Composite materials (GRP) • Thermoplastics such as HDPE, PVC, PPH, PVDF, PVC-C, ECTFE, and PFA • Metal construction

Metal construction is a building process that primarily uses steel as a structural material. It involves assembling metal elements such as frames. This type of construction is valued for its strength, durability, speed of implementation, and ability to create large-span structures, such as industrial warehouses.

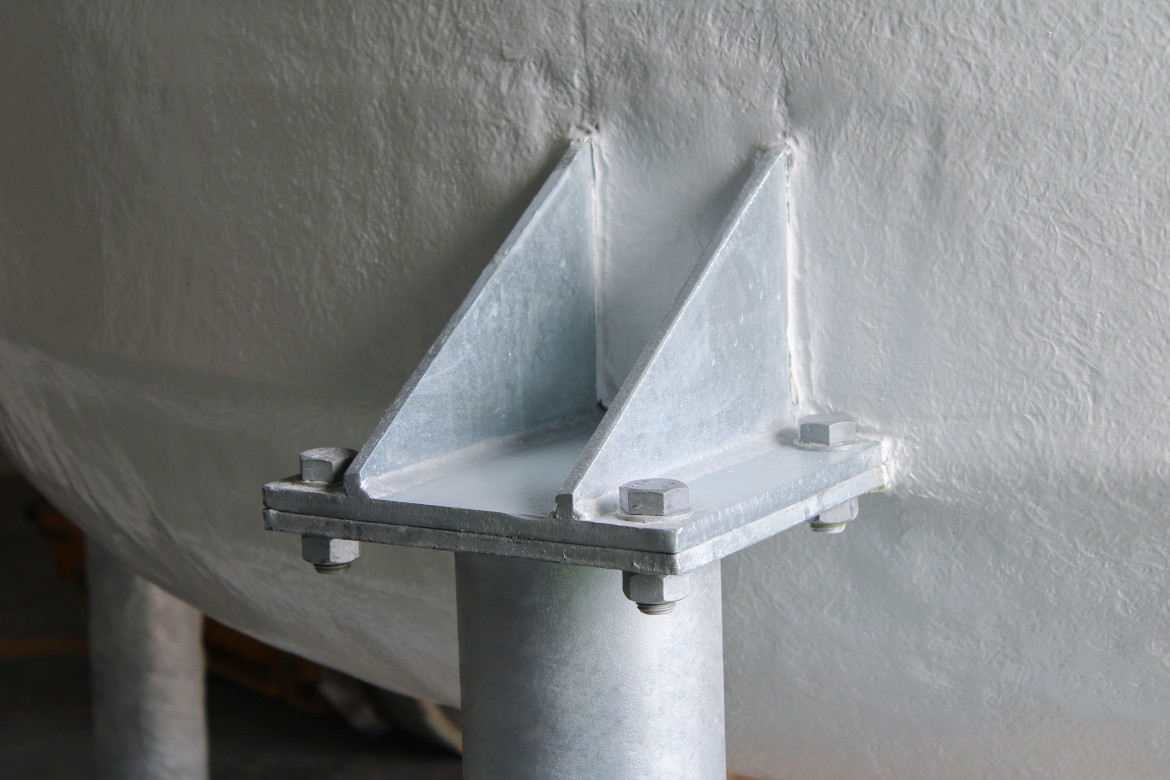

GCER manufactures various types of metal construction, including : • Steel structures : Solid structures for industrial buildings • Ladders with cage for safe access at height • Platforms, handrails and stairs : solutions for safety and movement on site • Pipe supports and racks : for organizing and maintaining pipes • Steel skids : structures for supporting, transporting, and installing complete equipment in a single unit

Metal construction can be more expensive than concrete in terms of initial costs, as metal materials and specialized labor can be more costly. However, metal offers advantages such as lightness, speed of assembly, and better resistance in certain environments, which can reduce other costs in the long term, particularly for maintenance and durability. The choice between metal and concrete will depend on project specifications, conditions of use, and long-term performance criteria.

Yes, at GCER, we frequently combine metal with other materials. For example, when building a platform, combining a metal structure with GRP grating provides a lightweight, durable, and corrosion-resistant solution, while also facilitating installation and optimizing safety.

When galvanized or painted, metal structures require little maintenance. A simple periodic inspection is sufficient to check the condition of the protective coating and ensure the durability of the structure. In the event of damage, minor repairs are usually sufficient to keep the structure in good condition for many years.