GCER is distinguished by its remarkable production capacity for GRP (Glass Reinforced Plastic) industrial pipes, offering a wide range of pipes and accessories adapted to the specific needs of industry. With our expertise in the use of different resins such as polyester and vinylester, we are able to respond precisely to the varied requirements of our customers for their industrial projects.

Our expertise in the production of PRV industrial pipes enables us to offer suitable solutions for both underground and overhead applications, with our advanced filament winding technique.

We offer a wide range of grp piping , covering nominal diameters from DN 80 to DN 1800, with the possibility of custom orders for larger diameters.

Our GRP industrial pipes are used in a variety of sectors, including :

GCER has developed an advanced fire fighting solution specifically designed for demanding industries such as oil and energy. Our hoses use a special resin enriched with additives to enhance their fire resistance, complying with the following rigorous standards:

This approach guarantees maximum protection against fire, ensuring the safety and reliability of critical industrial installations.

The world of composite materials is expanding spectacularly, promising an even brighter future. Some experts are even talking about the age of composites. GRP pipes stand out for their exceptional features and benefits, offering an optimum combination of cost and durability. Ideal for a wide range of applications, these innovative products guarantee reliable performance and remarkable longevity, perfectly meeting modern requirements.

| Caractéristiques | Avantage |

| La corrosion |

|

| Légèreté (1/4 du poids de l’acier ou de la fonte et 1/10 du poids du béton) |

|

| Longueur utile des tubes (6,12m) |

|

| Surface intérieure lisse |

|

| Système de fabrication respectant les normes de fabrication les plus strictes |

|

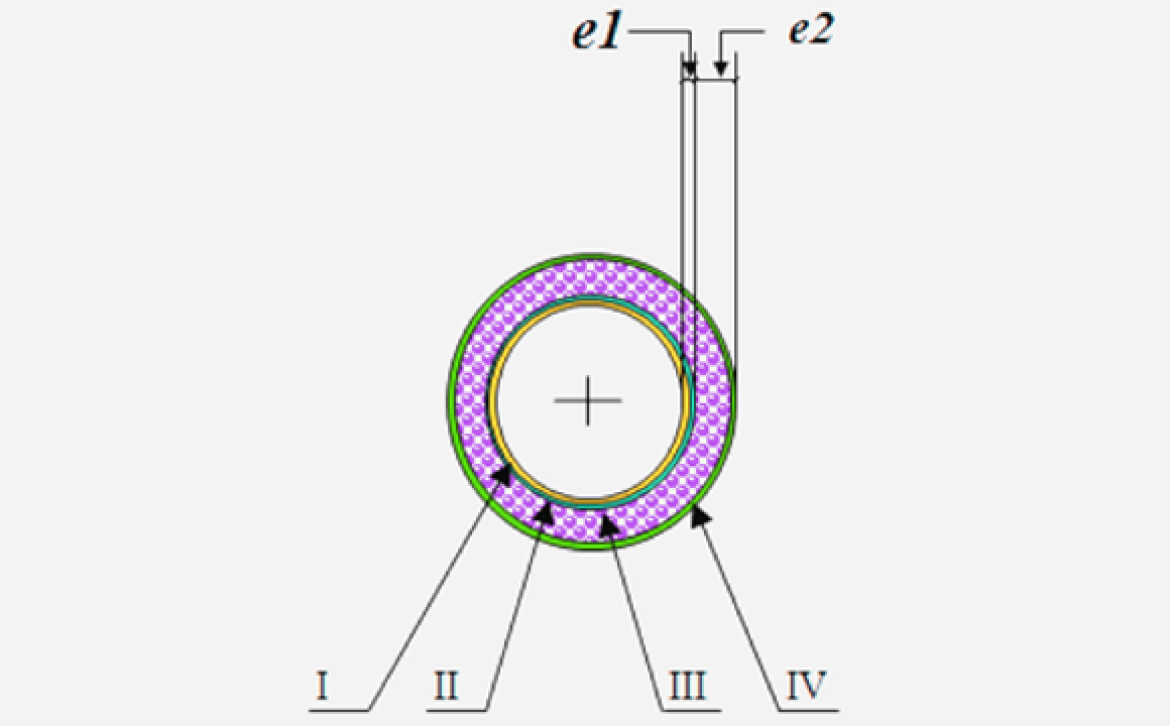

A resin-rich layer, the thickness of the layer and the type of resin depend on the nature of the fluid in the tube and the operating conditions.

Manufactured by filament winding from continuous fiberglass yarns coated with vinylester or polyester resin, and deposited on a rotating mandrel by a machine.

The machine consists of a rotating mandrel, a dispensing arm that moves along the rotating mandrel, depositing the material at a defined angle, a storage area for the fiberglass and a resin bath.

The mandrel can be replaced by a tube of the required material, which then forms the liner of the tube.

This manufacturing technique allows the use of fiberglass reinforcement in the circumferential direction.

When these pipes are used in underground or high-pressure applications, the majority of loads are concentrated in the circumferential direction of the pipe, which is why the incorporation of continuous glass fiber reinforcement in this direction results in a more efficient product.

Winding angle is a fundamental parameter in all GRP pipes manufactured by filament winding.

This angle directly governs the relationship between the circumferential and axial characteristics of the designed tube, that is, the relationship between the axial pressure (axial tensile strength).

A pipe designed with a winding angle exceeding 65° is a pipe with optimal circumferential properties but low axial efficiency.

For underground installations, a winding angle close to 65° is proposed to ensure superior resistance against ground load, vertical loads and internal pressure.

On the other hand, for overhead installations, the winding angle will be close to 55°, as the tube must be supplied with superior characteristics in the axial direction.

Silica can also be used to increase tube rigidity.

GCER offers a wide range of tubes and accessories designed to meet the specific requirements of every industrial application. Our products are available in a variety of diameters, pressures and stiffnesses to suit our customers' diverse needs.

Technical specifications :

Each size and specification is carefully selected to ensure optimum performance and compatibility with a variety of industrial applications, from water treatment projects to chemical and petroleum applications.

The methods used to assemble composite tubes play a crucial role in their performance and durability. Here are a few commonly used techniques :

The Spigot-Bell assembly is widely preferred for its many advantages:

This type of connection guarantees a permanent bond by using glass-fiber reinforcements and resin for lamination. Laminate thickness and width depend on tube diameter and specific operating pressures.

Flange assembly is used to connect pipes to other system components, such as valves or similar equipment. This method allows rapid installation and dismantling, facilitating maintenance and system modifications.

GRP (Glass Reinforced Polyester) is a composite material combining polyester resin and glass fibers. This combination gives it high mechanical strength, excellent durability, and remarkable chemical resistance.

GRP (Glass Reinforced Polyester) is a composite material offering an exceptional combination of lightness, mechanical strength, and durability. It is distinguished by its high resistance to corrosion, chemicals, and extreme environmental conditions, making it ideal for a wide range of industrial applications. In addition, its design flexibility allows for the manufacture of custom structures, optimizing the performance and longevity of equipment.

GRP (Glass Reinforced Polyester) cannot be recycled in the same way as traditional plastics. Due to its composite composition—a polymer matrix reinforced with glass fibers—conventional mechanical recycling is difficult. However, there are specialized processes for recovering end-of-life materials, including energy recovery or grinding techniques and reuse in secondary applications (fillers, construction materials, etc.). In addition, research is underway to develop more sustainable recycling methods for composites. GCER remains attentive to these technological developments in order to integrate environmentally friendly solutions into its processes.

GCER is located in Ksibet Sousse, Tunisia, specifically on Route de Thrayet. For any information requests, you can contact us : By phone: +216 73 238 960 / +216 70 015 590 By email: commercial@gcertunisie.tn Or directly via our online contact form: https://gcertunisie.com/demande-de-contact

To obtain a quote, please fill out the quote request form on our website or contact our sales team directly by email at the following address : commercial@gcertunisie.tn We will respond as soon as possible.

GCER is certified: ✅ ISO 9001:2015 – Quality management systems ✅ ISO 14001:2015 – Environmental management systems ✅ ISO 45001:2018 – Occupational health and safety management systems ✅ MSI (Materials, Systems, Installations) – Technical certification guaranteeing the compliance of products and processes with specific sector requirements ✅ Authorized Economic Operator (AEO) – Customs recognition attesting to the reliability of the company in the international supply chain These certifications demonstrate GCER's commitment to quality, safety, regulatory compliance, and customer satisfaction, while ensuring reliable, sustainable, and certified solutions.

GRP (Glass Reinforced Polyester) equipment has a service life of between 30 and 50 years, depending on conditions of use and maintenance. Its resistance to corrosion and low maintenance requirements ensure a long service life. Regular maintenance helps to preserve its performance and maximize its service life.

We use several GRP manufacturing technologies, including filament winding, contact molding, and simultaneous projection, to ensure that our equipment is durable and complies with the most stringent international standards.

Yes, we offer an assembly service for all our equipment. Our technical team ensures that assembly complies with standards, guaranteeing optimal installation and reliable operation of your products.

Manufacturing and delivery times depend on the project. We are committed to providing you with fast solutions tailored to our customers' needs.

At GCER, the manufacturing process involves several steps : 1. Research and design : We begin by studying each customer's specific needs in order to design tailored solutions. 2. Manufacturing : The equipment is manufactured in our workshops. 3. Quality control : We check the compliance of each piece of equipment during manufacturing. 4. Testing : Each piece of equipment is tested before delivery. 5. Delivery : The equipment is delivered to the project site on schedule. 6. On-site installation : Our teams install the equipment on site quickly and efficiently.

At GCER, we offer comprehensive solutions for your industrial projects, taking care of every step from design to commissioning. With us, you benefit from a single partner who ensures optimal coordination, on-time delivery, and consistent quality. Our solutions are tailored to your specific needs, backed by our expertise and rigorous monitoring. Contact us today for your industrial projects.

GCER operates in various sectors, including : • Water and water desalination • Wastewater • Chemicals • Agri-food • Energy • Mining • Oil • Environment • Industrial processes

GCER specializes in : • Composite materials (GRP) • Thermoplastics such as HDPE, PVC, PPH, PVDF, PVC-C, ECTFE, and PFA • Metal construction

To find out if thermoplastic or GRP equipment has reached the end of its service life, check for : • Cracks or deformations. • Loss of resistance to stress. • Leaks or damaged seals. • Reduced performance after testing or inspections. It is important to follow the manufacturer's recommendations and carry out regular checks.

GRP (Glass Reinforced Polyester) is generally more expensive than thermoplastics. This difference is due to a more complex manufacturing process and the use of reinforced materials. However, GRP offers better mechanical and chemical resistance, making it ideal for demanding applications.

GRP (Glass Reinforced Polyester) pipes offer many advantages : they are highly resistant to corrosion, lightweight and easy to install, and require little maintenance. They are also durable with a long service life, and offer good thermal insulation, making them a reliable and economical solution for many industrial environments.

Our GRP (Glass Reinforced Polyester) pipes are suitable for transporting a wide range of fluids, including chemicals, drinking water, wastewater, hydrocarbons, and other industrial liquids. With their corrosion resistance, they can be used for aggressive and corrosive fluids in extreme conditions.