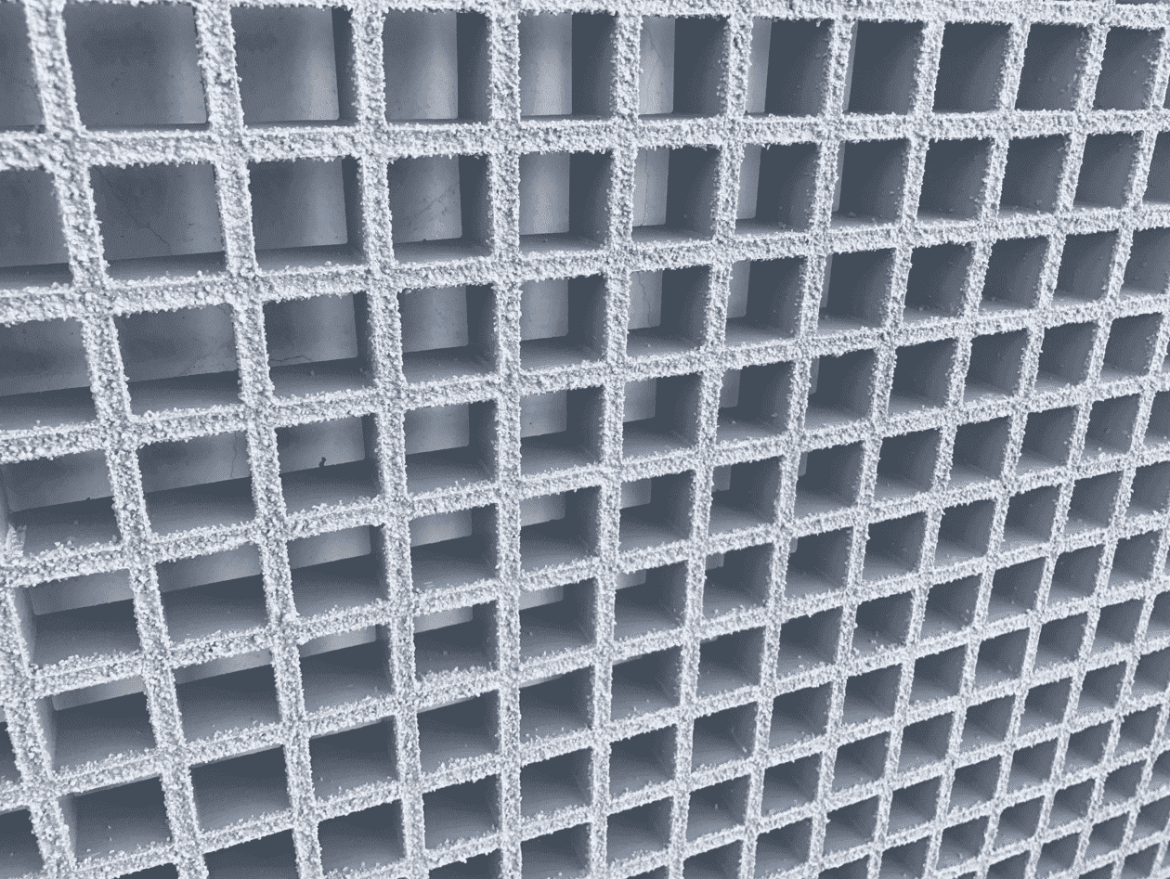

GRP gratings represent an advanced and effective flooring solution for industrial and corrosive environments. These composite structures, such as AERON composite gratings, are designed to offer exceptional resistance to load and corrosion, while being lightweight and durable. By incorporating high quality materials, including UV inhibitors and specific additives, GCER's GRP gratings are reinforced with glass fibres to ensure optimum performance in a variety of industrial applications.

GRP gratings are much lighter than their metal counterparts, making them easier to handle and install.

The anti-corrosion properties of the resins used guarantee a long service life, even in highly corrosive environments.

As electrical insulators, GRP grating offer increased safety in applications where electricity is present.

Their anti-slip surface ensures optimum safety, reducing the risk of slips and falls.

The flat, uniform surface of GRP gratings allows for unobstructed passage, ideal for environments requiring smooth traffic flow.

The durability and strength of the materials used minimize maintenance requirements, reducing long-term costs.

GRP gratings are available in a variety of sizes, shapes, colors and resin types to adapt to different applications.

| GRP GRATINGS | STANDARD PANEL DIMENSIONS |

| ISO38 thickness 38 and Mesh 31 x 31 mm | 1220m x 3660 mm |

| ISO30 thickness 30 and Mesh 31 x 31 mm | 1000 x 4000 mm |

| ISO38 thickness 38 and Mesh 13 x 13 mm | 1000 x 4000 mm |

| ISO40 thickness 40 and Mesh 76 x 76 mm | 1000 x 4000 mm |

Custom sizes can be manufactured to meet specific customer requirements.

GRP gratings are generally rectangular in shape, but can also be designed in square, circular or triangular shapes, according to customer specifications.

Our standard panels are grey. However, other colours are available to meet customers' aesthetic and functional requirements.

Gratings can be manufactured from different types of resin, depending on the chemical aggressiveness of the environment. Polyester or vinyl ester resins are commonly used to ensure optimum resistance.

GRP gratings are manufactured in a single block, which gives them high load resistance, as shown in the following table :

| Portée en (mm) | Charge ponctuelle (kg) | Facteur de sécurité | Charge repartie (kg/m²) | Facteur de sécurité |

| 300 | 3.580 | 2 x F | 18.600 | 3 x q |

| 450 | 1.550 | 3 x F | 5.500 | 4 x q |

| 600 | 870 | 4 x F | 2.340 | 5 x q |

| 750 | 560 | 5 x F | 1.190 | 7 x q |

| 900 | 387 | 6 x F | 690 | 8 x q |

| 1000 | 314 | 7 x F | 503 | 9 x q |

| 1200 | 218 | 8 x F | 290 | 10 x q |

GRP gratings are versatile and can be used in a variety of industrial and environmental sectors. Here are just a few examples of applications :

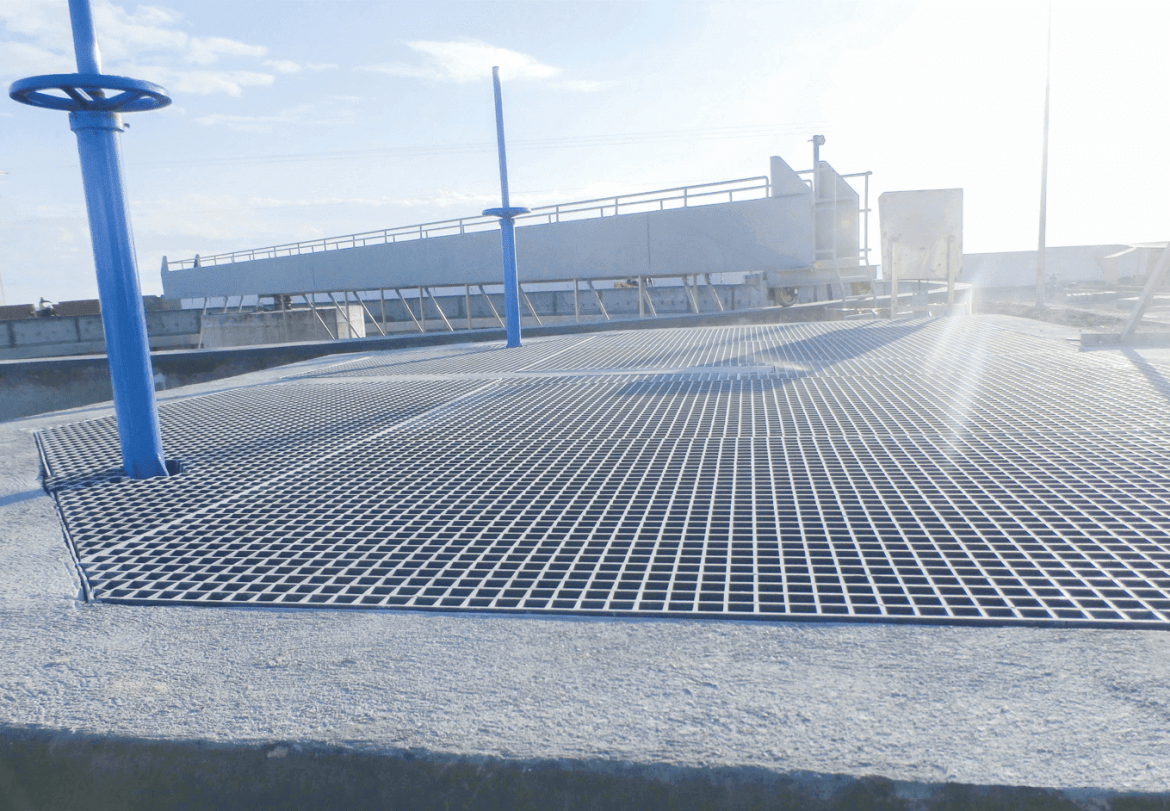

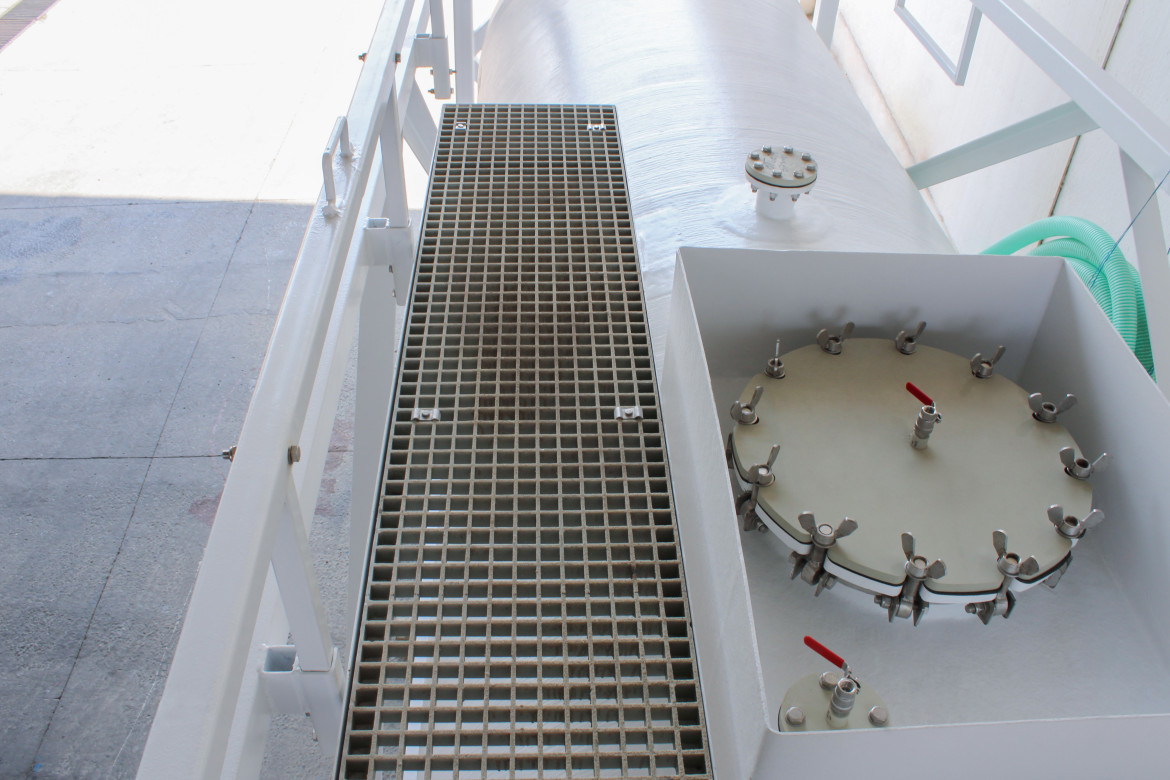

GRP gratings are ideal for the aggressive environments encountered in the water treatment, chemical, mining and oil industries. With their anti-slip, non-conductive and corrosion-resistant properties, these gratings offer a safe and cost-effective solution for platforms and walkways, increasing worker safety and plant durability.

In the transport industry, characterized by harsh weather conditions and corrosive elements, GRP gratings are used for pedestrian traffic areas and stair treads. They ensure safety and require little maintenance, even in extreme conditions such as tank filling and emptying areas.

Food and beverage production environments, often corrosive and humid, benefit greatly from GRP gratings. Resistant to acid solutions and with anti-slip properties, these gratings require little maintenance and ensure greater safety in production and cleaning areas.

In recreational facilities such as water parks, zoos, marinas and aquariums, GRP gratings offer exceptional corrosion resistance and safety. They are ideal for walkways, feeding areas, swimming pools, park equipment and other areas requiring protection against moisture and wear.

GRP gratings are equally versatile for a variety of other industrial and commercial applications. They are used for platforms, walkways, stairs, gutter covers and internal equipment supports, offering a reliable and durable solution to ensure safety and efficiency in a variety of uses.

GRP (Glass Reinforced Polyester) is a composite material combining polyester resin and glass fibers. This combination gives it high mechanical strength, excellent durability, and remarkable chemical resistance.

GRP (Glass Reinforced Polyester) is a composite material offering an exceptional combination of lightness, mechanical strength, and durability. It is distinguished by its high resistance to corrosion, chemicals, and extreme environmental conditions, making it ideal for a wide range of industrial applications. In addition, its design flexibility allows for the manufacture of custom structures, optimizing the performance and longevity of equipment.

GRP (Glass Reinforced Polyester) cannot be recycled in the same way as traditional plastics. Due to its composite composition—a polymer matrix reinforced with glass fibers—conventional mechanical recycling is difficult. However, there are specialized processes for recovering end-of-life materials, including energy recovery or grinding techniques and reuse in secondary applications (fillers, construction materials, etc.). In addition, research is underway to develop more sustainable recycling methods for composites. GCER remains attentive to these technological developments in order to integrate environmentally friendly solutions into its processes.

Yes, we specialize in custom design. Our engineers work collaboratively with our customers to develop solutions tailored to their requirements.

GCER is located in Ksibet Sousse, Tunisia, specifically on Route de Thrayet. For any information requests, you can contact us : By phone: +216 73 238 960 / +216 70 015 590 By email: commercial@gcertunisie.tn Or directly via our online contact form: https://gcertunisie.com/demande-de-contact

To obtain a quote, please fill out the quote request form on our website or contact our sales team directly by email at the following address : commercial@gcertunisie.tn We will respond as soon as possible.

GCER is certified: ✅ ISO 9001:2015 – Quality management systems ✅ ISO 14001:2015 – Environmental management systems ✅ ISO 45001:2018 – Occupational health and safety management systems ✅ MSI (Materials, Systems, Installations) – Technical certification guaranteeing the compliance of products and processes with specific sector requirements ✅ Authorized Economic Operator (AEO) – Customs recognition attesting to the reliability of the company in the international supply chain These certifications demonstrate GCER's commitment to quality, safety, regulatory compliance, and customer satisfaction, while ensuring reliable, sustainable, and certified solutions.

GRP (Glass Reinforced Polyester) equipment has a service life of between 30 and 50 years, depending on conditions of use and maintenance. Its resistance to corrosion and low maintenance requirements ensure a long service life. Regular maintenance helps to preserve its performance and maximize its service life.

Yes, we offer an assembly service for all our equipment. Our technical team ensures that assembly complies with standards, guaranteeing optimal installation and reliable operation of your products.

Manufacturing and delivery times depend on the project. We are committed to providing you with fast solutions tailored to our customers' needs.

At GCER, the manufacturing process involves several steps : 1. Research and design : We begin by studying each customer's specific needs in order to design tailored solutions. 2. Manufacturing : The equipment is manufactured in our workshops. 3. Quality control : We check the compliance of each piece of equipment during manufacturing. 4. Testing : Each piece of equipment is tested before delivery. 5. Delivery : The equipment is delivered to the project site on schedule. 6. On-site installation : Our teams install the equipment on site quickly and efficiently.

At GCER, we offer comprehensive solutions for your industrial projects, taking care of every step from design to commissioning. With us, you benefit from a single partner who ensures optimal coordination, on-time delivery, and consistent quality. Our solutions are tailored to your specific needs, backed by our expertise and rigorous monitoring. Contact us today for your industrial projects.

GCER operates in various sectors, including : • Water and water desalination • Wastewater • Chemicals • Agri-food • Energy • Mining • Oil • Environment • Industrial processes

GCER specializes in : • Composite materials (GRP) • Thermoplastics such as HDPE, PVC, PPH, PVDF, PVC-C, ECTFE, and PFA • Metal construction

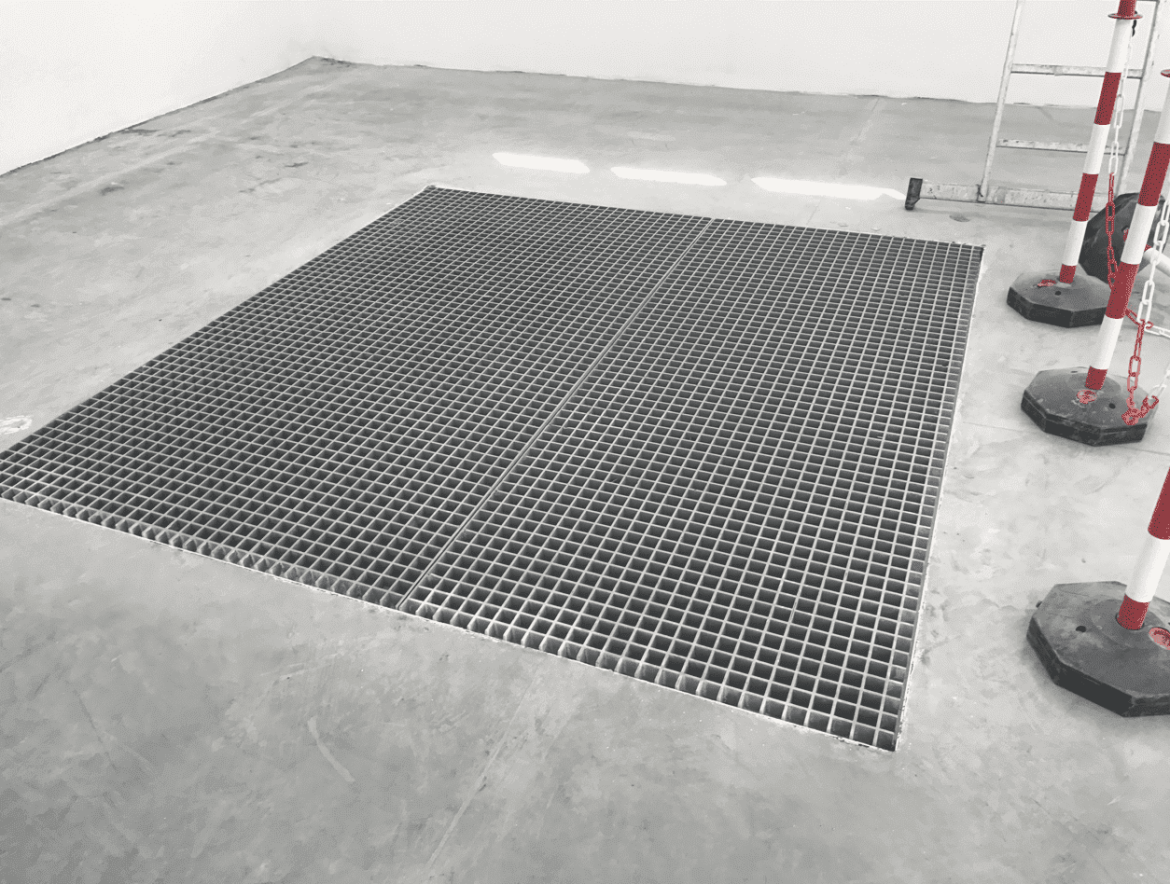

A grating is an openwork structure composed of mesh (often square or rectangular), used primarily as anti-slip flooring in industrial areas, walkways, platforms, or wet areas. It allows liquids to drain, provides ventilation, and offers good mechanical strength.

The grating is designed to : • Create safe walking surfaces. • Allow water or chemicals to drain away. • Offer good load-bearing capacity and corrosion resistance. • Maintain a non-slip surface in slippery environments.

GRP grating offers many advantages : • Excellent corrosion resistance : suitable for chemical, marine, or humid environments • Lightweight : easier to handle and install than traditional metal materials • High mechanical strength : withstands heavy loads while maintaining its shape • Non-slip surface : improves safety in walkways, even in wet conditions • Low maintenance : does not rust and does not require regular treatment • Extended service life : excellent durability even in extreme conditions • Electrical insulation : non-conductive material, ideal for environments with electrical hazards • UV and weather resistance : suitable for outdoor use

GRP (Glass Reinforced Polyester) gratings are a high-performance alternative to steel due to their light weight, corrosion resistance, and durability in aggressive environments (chemical, marine, humid, etc.). Unlike steel, they do not rust, require no anti-corrosion treatment, and need very little maintenance. Their non-slip surface improves user safety, and their low electrical conductivity makes them suitable for sensitive environments. They therefore offer a reliable, economical, and sustainable technical solution.

Our GRP (Glass Reinforced Polyester) gratings are frequently used in conjunction with other industrial equipment, such as metal platforms, to create integrated and optimized solutions. This combination ensures the safety, stability, and durability of installations, even in particularly demanding industrial environments.

GRP (Glass Reinforced Polyester) gratings are available in several standard sizes depending on the model : • ISO30 (thickness 30 mm, mesh size 31 x 31 mm): 1000 x 4000 mm • ISO38 (thickness 38 mm, mesh size 31 x 31 mm): 1220 x 3660 mm • ISO38 (thickness 38 mm, mesh size 13 x 13 mm): 1000 x 4000 mm • ISO40 (thickness 40 mm, mesh size 76 x 76 mm): 1000 x 4000 mm Custom dimensions can be manufactured to meet the specific needs of each project, ensuring a perfect fit for your installations.

Standard GRP (Glass Reinforced Polyester) grating shapes are rectangular, but they can also be custom-made in square, circular, triangular, or any other shape according to specific customer requirements.

The standard color for GRP (Glass Reinforced Polyester) gratings is gray. Other colors are available on request to meet specific aesthetic or functional requirements (visibility, industrial color coding, etc.).

An access hatch is a closure (often solid or partially openwork) that provides access to, or closure of, an opening such as a manhole, tank or inspection chamber etc. It can be hinged, removable or lockable depending on its intended use.

The access hatch is used to : • Close or secure an opening (manhole, technical room, tank, etc.). • Provide occasional access for maintenance, inspection, or cleaning. • Ensure watertightness, safety, or protection against intrusion.

In some cases, reinforced grating can be used as a cover or openwork hatch, particularly when ventilation or drainage is required. However, for watertight or secure closure functions, a specific hatch is recommended.

Although often found in the same environments, gratings and access hatches have very distinct uses and characteristics : • Main function : - The grating is an openwork surface designed to allow people or fluids to pass through. - The access hatch is mainly used to close or provide access to an opening. • Structure : - The grating is generally made of openwork mesh. - The access hatch is solid or semi-openwork, depending on the sealing or safety requirements. • Installation : - The grating is fixed to the floor and can be installed in a raised or suspended position. - The access hatch is placed over an opening and is often movable (removable or hinged). • Access : - The grating is not designed to be easily removed, as it is an integral part of the passageway structure. - The access hatch is designed to be easily opened or removed to allow direct access. • Example of use : - Grating is used for walkways, raised floors, or traffic areas, etc. - Access hatches are used for manholes, inspection hatches, or tank access, etc.

The standard dimensions of GRP (Glass Reinforced Polyester) access hatches vary depending on the model : • P38 – Thickness 41 mm : 1220 x 3660 mm • P30 – Thickness 33 mm : 1000 x 4000 mm • P40 – Thickness 41 mm : 1000 x 4000 mm Custom sizes can be manufactured to meet specific customer requirements.