Industry 4.0, often described as the fourth industrial revolution, represents a significant step forward for many companies, including GCER. This transition involves the adoption of cutting-edge technologies and the integration of digital systems to create more connected, intelligent and efficient production environments. For GCER, this evolution is not only a strategic necessity, but also an opportunity to position itself as a leader in an increasingly competitive and demanding market.

GCER relies on a meticulous approach to data analysis and the integration of digital technology to strengthen its internal processes. This integration strategy enables real-time monitoring of the performance of its equipment and systems. This monitoring not only facilitates the detection and rapid resolution of anomalies, but also makes it possible to predict and prevent breakdowns through a predictive maintenance approach. As a result, the company is able to reduce downtime, optimise operational efficiency and control maintenance costs.

GCER's transition to Industry 4.0 opens the door to a host of benefits :

By integrating data analysis, GCER can identify and eliminate inefficiencies in its operations. Processes can be continuously monitored and adjusted in real time, leading to improved productivity and reduced lead times.

Numerical technologies enable more accurate and rapid quality control. Automated systems can detect defects earlier in the production process, ensuring better compliance with quality standards and a reduction in defective products.

By optimising processes and improving quality, GCER can significantly reduce its operating costs. Less waste, fewer returns of faulty products and more efficient use of resources all contribute to substantial savings.

The ability to rapidly adopt new technologies and integrate innovations gives GCER a competitive edge. This enables the company to respond more quickly to market changes and customer demands, consolidating its market position.

Industry 4.0 encourages a culture of innovation at GCER. The company can explore new business models, develop more customised products and services, and exploit emerging technologies to create added value.

Customer data and digital technologies enable GCER to offer tailor-made products and services that respond precisely to customers' individual needs and preferences. This personalisation enhances customer satisfaction and loyalty.

Digital technologies enable richer and more direct interaction with customers at GCER. The company can gather feedback in real time, improve the customer experience and build stronger, longer-lasting relationships with its customers.

Investing in digital transformation is essential to thrive in a VUCA (volatile, uncertain, complex and ambiguous) environment. Industry 4.0 provides GCER with the tools it needs to navigate this complex environment. For example, the flexibility and agility of digital production systems enable the company to adapt quickly to market changes and new customer demands.

Machinery plays a crucial role in achieving highly automated, precise and adaptable production. The following article looks in detail at each piece of GCER equipment and its impact on the manufacturing process.

This machine is renowned for its exceptional precision, operational efficiency and integration of advanced technologies. Designed to optimise production, reduce costs and improve the quality of finished products, its adoption by GCER brings multiple benefits that strengthen its competitiveness and performance on the market.

The roll slitter is renowned for its precision and reliability. It enables clean, efficient cutting on a variety of materials, facilitating a significant improvement in the efficiency and quality of production processes at GCER. Its adoption strengthens the company's competitiveness by meeting high market standards.

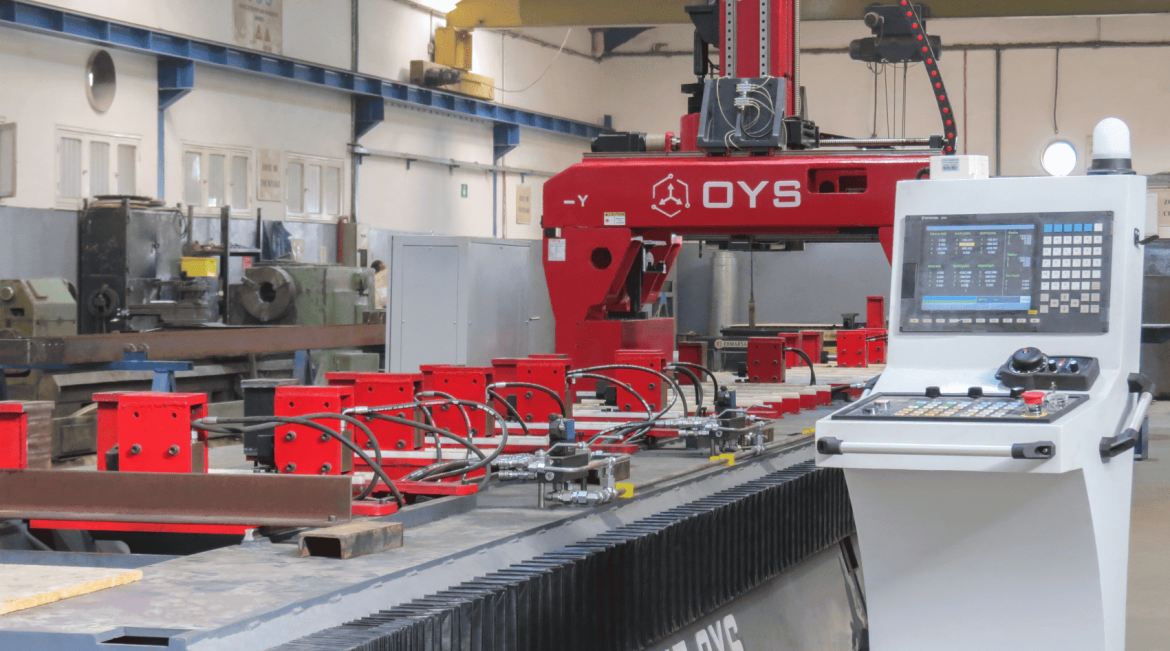

OYS' 3-axis and 5-axis router machines are renowned for their precision and ease of use. They enable the GCER to cut and sculpt various materials with great precision, improving the efficiency and quality of our production.

This machine is specially designed for milling and precision cutting of various materials. It is the ideal tool for increasing precision and efficiency in production processes. This enables GCER to produce faster and with less waste, boosting its competitiveness and its ability to meet customer needs.

This machine offers fast, high-quality cuts on a wide range of materials, meeting strict industrial standards. Thanks to its high productivity and precision, it helps to improve the GCER's operational efficiency while ensuring top-quality results. This machine is essential for boosting competitiveness and responding effectively to the varied needs of customers.

The use of a high-pressure water jet enables precise cuts to be made on a variety of materials. This capability ensures clean, high-quality cuts that meet stringent industry standards, while improving the efficiency and competitiveness of GCER's manufacturing processes.

The bandsaw machine is designed to make fast, accurate cuts on a variety of materials, making it highly versatile to meet different production needs. Thanks to this capability, it effectively improves the efficiency of manufacturing processes at GCER while ensuring consistent quality of finished products, thereby strengthening its competitiveness on the market.

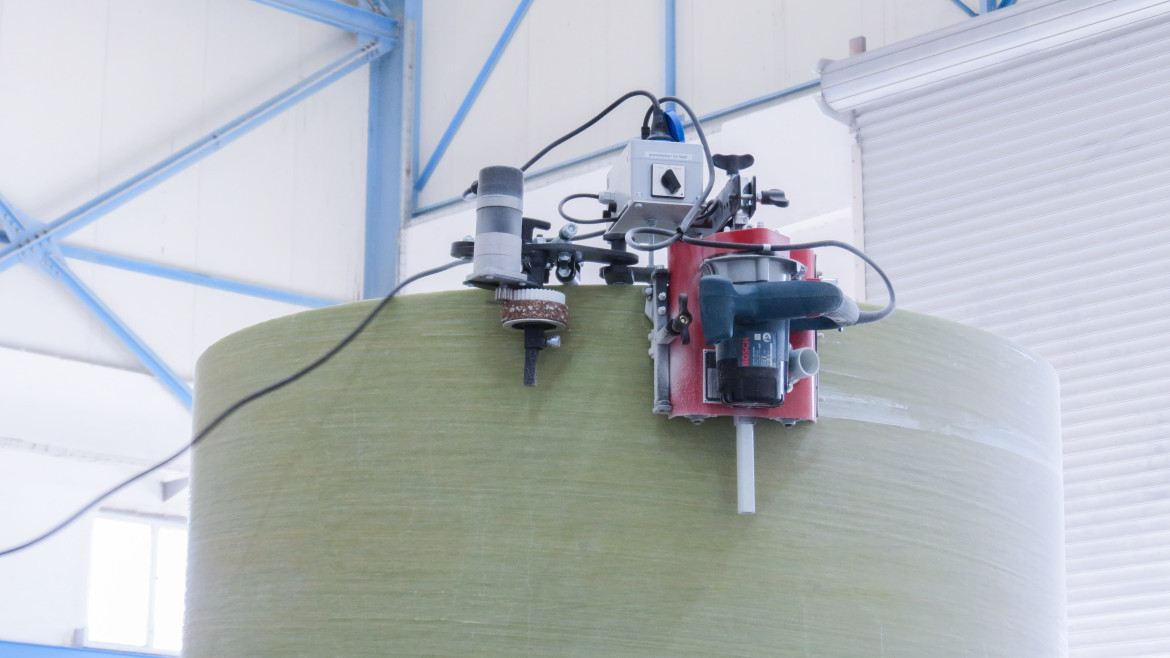

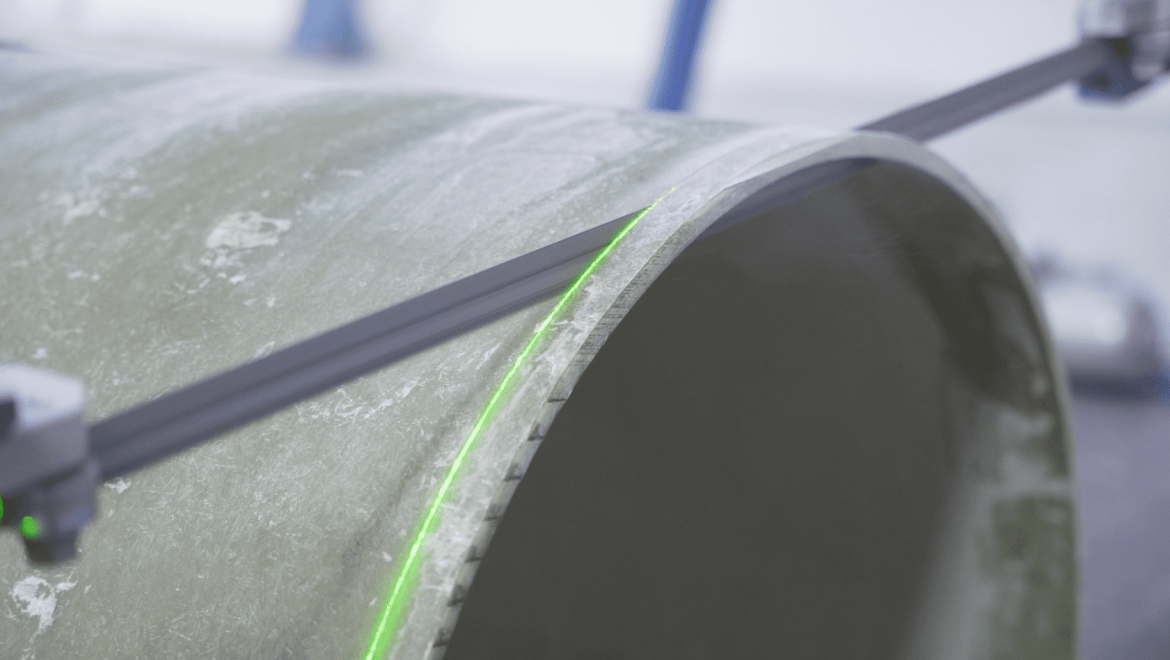

GCER manufactures 4 filament winding machines capable of handling diameters ranging from Ø 80 mm to Ø 7000 mm. These machines ensure uniform and efficient production of structural or reinforced composite parts, specifically designed to meet the requirements of our tube and boiler workshop.

The Polyfuse 630 and Polyfuse 315 machines use an automated fusion welding process to precisely assemble plastic parts. These machines produce strong welds suitable for a wide range of industrial applications, improving the quality and efficiency of products manufactured by GCER.

The use of CNC machines paves the way for agile, customised and flexible manufacturing. CNC systems allow production lines to be rapidly reconfigured to meet new market demands or specific customer specifications. This enables GCER to produce limited series or customised products without sacrificing efficiency or significantly increasing costs. What's more, this flexibility is a major asset in responding to market fluctuations and changing customer needs.

Industry 4.0 is not only synonymous with gains in efficiency and competitiveness, it also plays a crucial role in sustainability and respect for the environment. Digital technologies enable more efficient use of resources, reducing waste and energy consumption. GCER is committed to integrating sustainable practices into its production processes, thereby helping to protect the environment and reduce the industry's carbon footprint.