GCER is a leader in the engineering of plastic and thermoplastic piping and boilerwork, offering innovative and reliable solutions to meet the complex needs of industry. Our commitment to technical excellence, combined with our methodical approach and ability to integrate cutting-edge technologies, enables us to guarantee the quality, reliability and performance of our products at every stage of the process, from design to final delivery.

At GCER, our team of highly qualified engineers and technicians specialising in mechanical, electromechanical and industrial design are the backbone of our ability to offer customised solutions. Each member of our team brings valuable expertise accumulated over years of industry experience, enabling us to respond accurately and efficiently to the most complex technical challenges.

Our engineers are not only skilled in the design of plastic piping and boilerwork systems, they are also trained to anticipate and solve potential problems at the earliest stages of a project. Their commitment to innovation and their ability to use the latest modelling and simulation technologies ensure that every GCER solution is not only functional but also optimised for long-term performance and sustainability.

Our approach to manufacturing plastic and thermoplastic piping and boilerwork is based on a rigorous methodology that ensures quality and compliance with all relevant industry standards.

Here is a detailed overview of our processes :

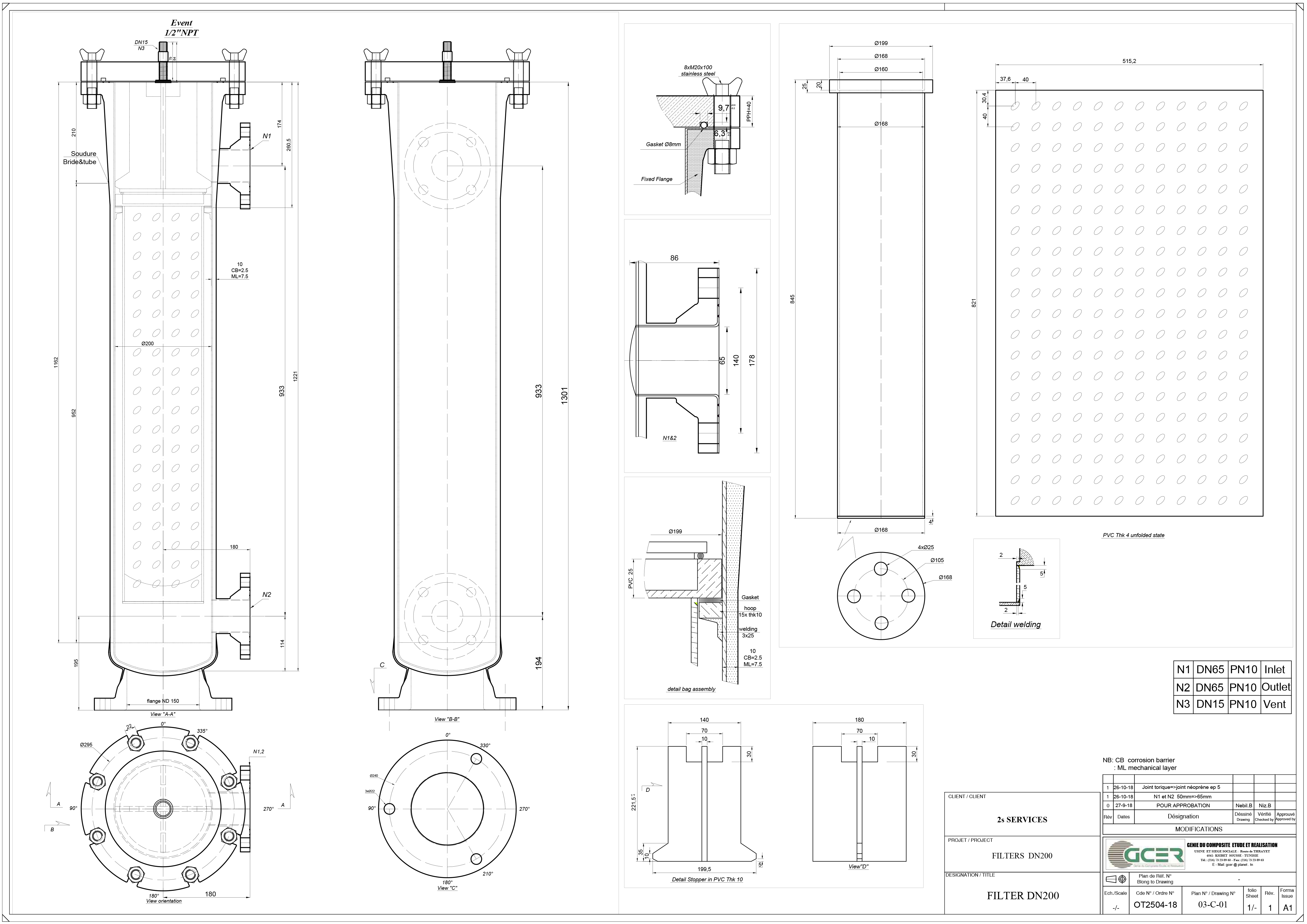

Every project begins with a detailed construction plan. This crucial phase clearly defines the project's technical and functional specifications, as well as the customer's specific requirements. Our engineers work closely with you to understand your needs and objectives, ensuring an accurate initial design and a solid foundation for the rest of the project.

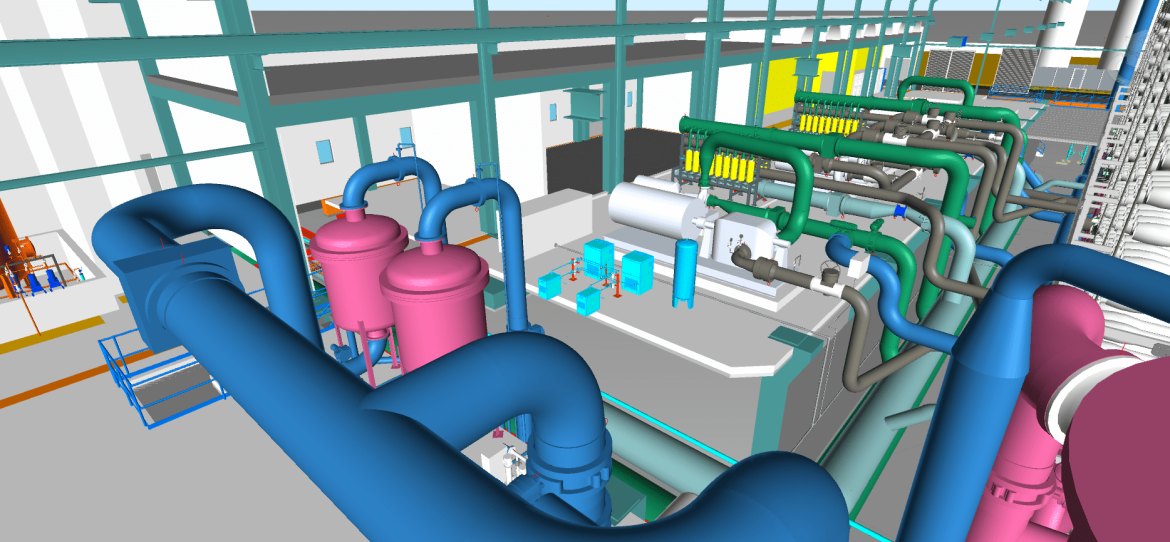

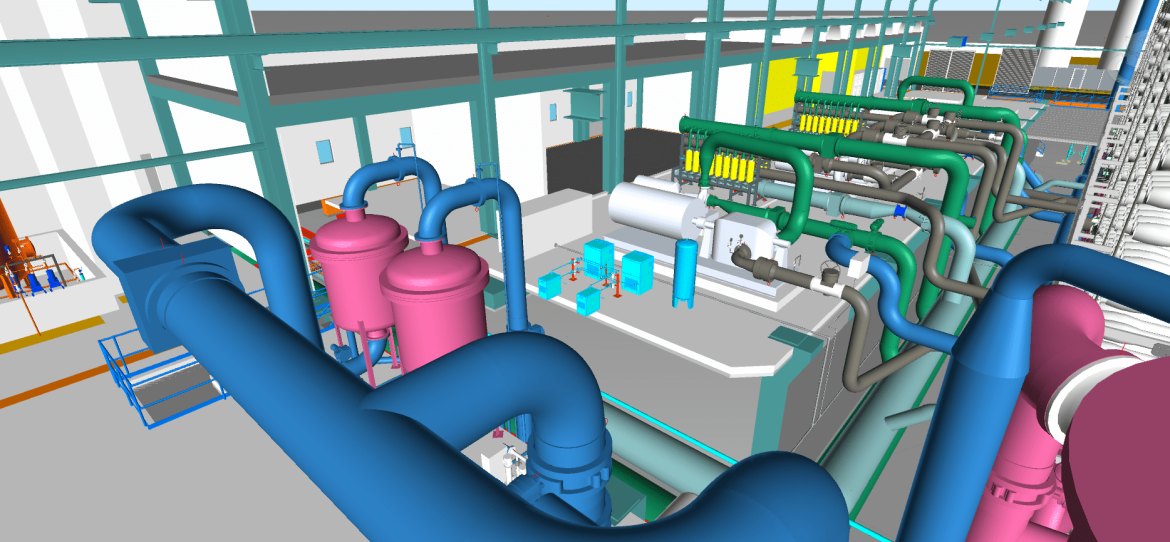

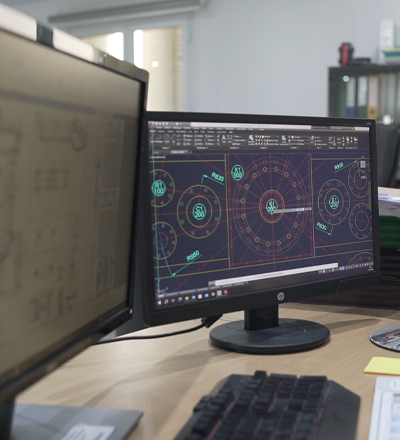

GCER offers custom design services using CAD software such as AUTOCAD or SOLIDEWORKS or CADWORK; we can produce detailed drawings to your exact specifications. We also manufacture equipment to your own approved drawings, offering maximum flexibility to our customers. This approach allows us to respond effectively to the specific requirements of each project, while maintaining technical consistency and precision at every stage of the manufacturing process.

We understand the importance of seamlessly integrating our products into your existing operations. That's why we offer the option of integrating your in-house coding into our construction drawings, simplifying the management of recurring projects and ensuring seamless compatibility with your in-house systems. This increased customisation ensures optimum operational efficiency and better resource management for our customers.

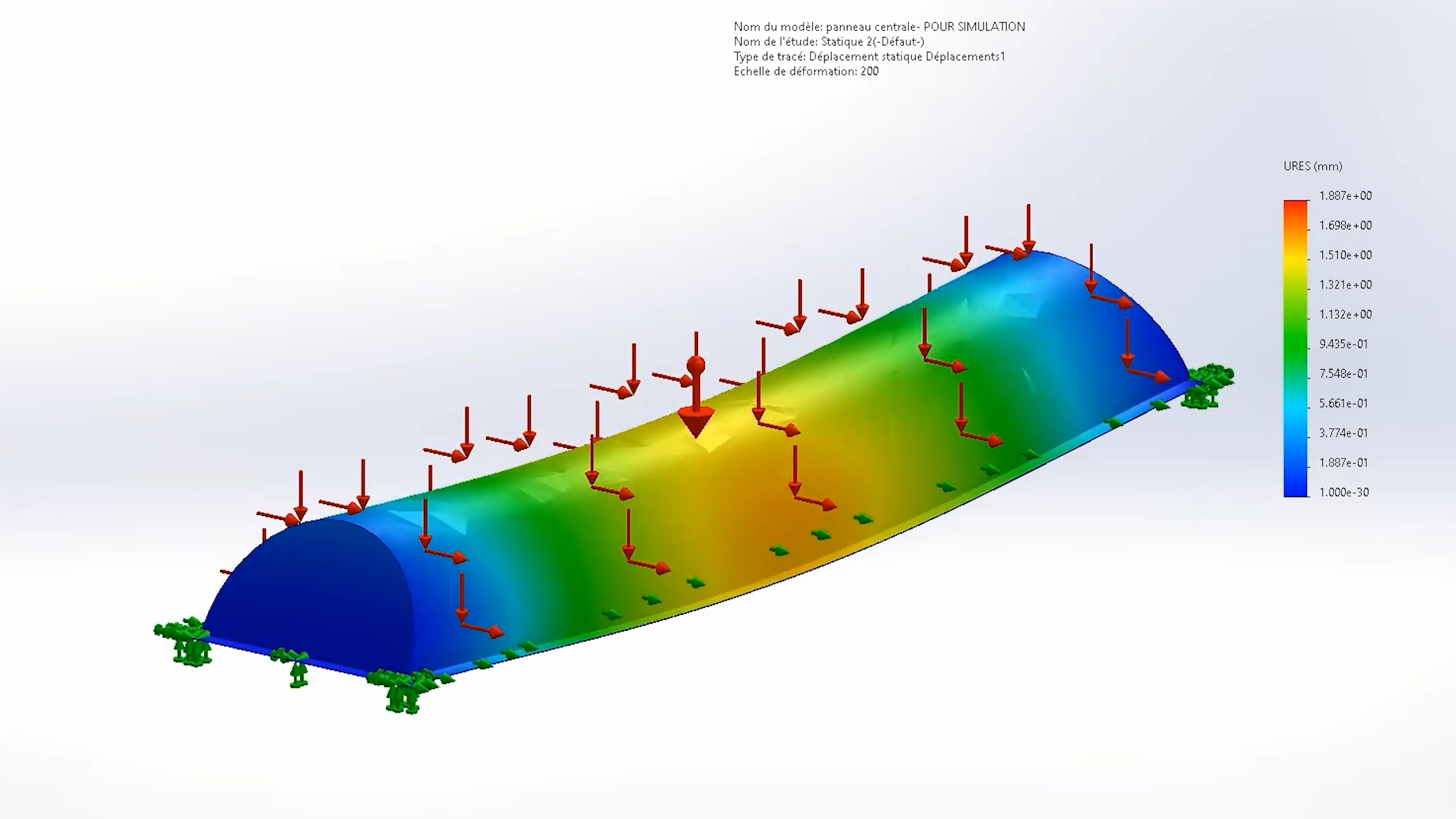

We offer specialist calculation expertise to optimise the design and performance of your equipment made from GRP materials, using two complementary approaches: the analytical method, which complies with EN13121 and ASME standards, and the finite element method (FEA).

• Use of analytical methods to assess strength, safety and durability in accordance with EN13121 and ASME X standards.

• Customised studies including the drafting of a hypothesis note validated by the customer, detailed calculations, in-depth analysis of the results, additional checks and the drafting of a detailed calculation note.

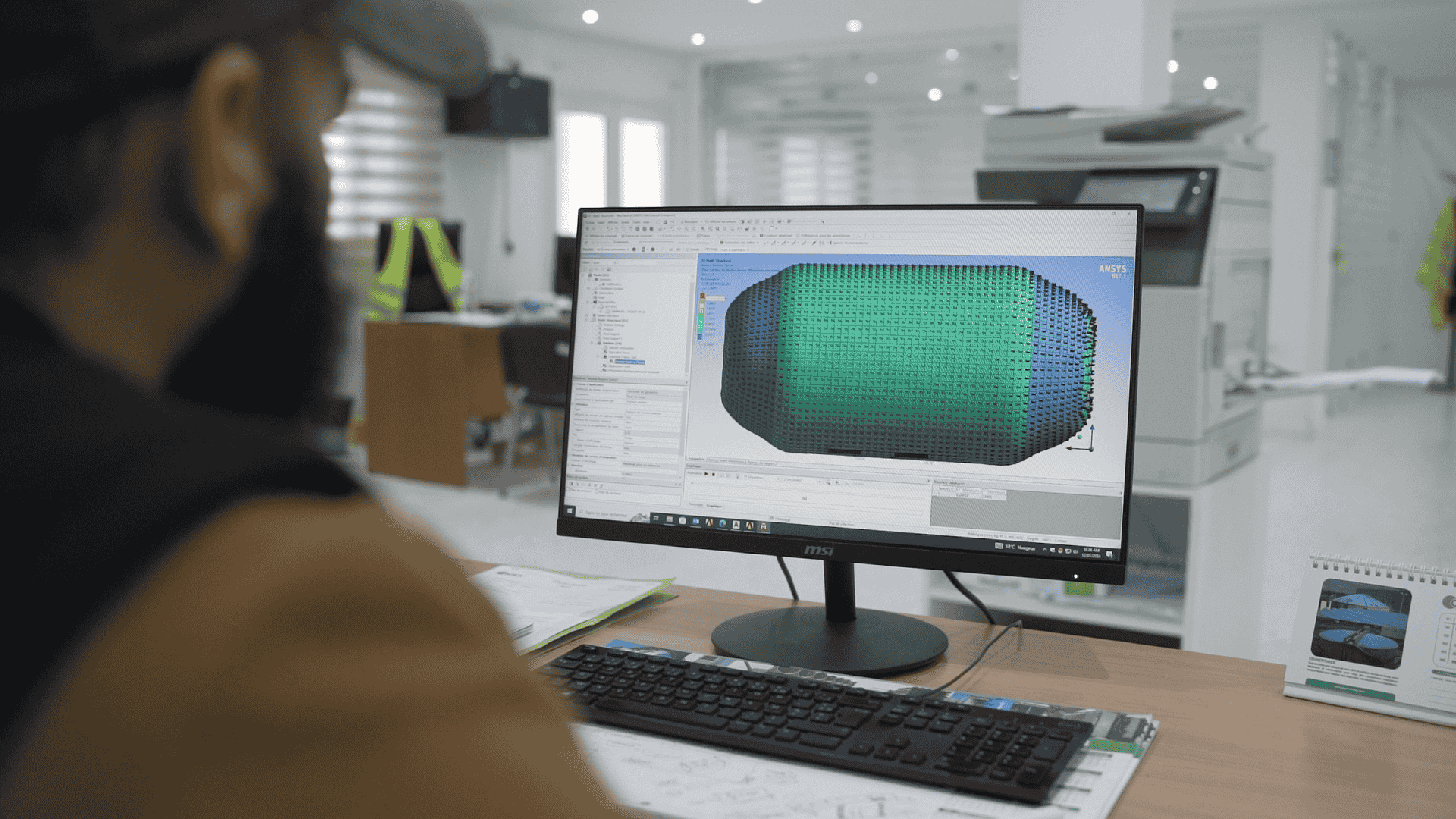

• Advanced modelling and simulation to predict the mechanical behaviour and performance of equipment under various types of load.

• Creation of finite element meshes to meet your specific quality criteria.

• Linear static analysis to determine stresses, strains and displacements.

• Modal calculations to identify eigenmodes and their deformation characteristics.

• Buckling calculations to assess critical modes and associated loads.

• Spectral analysis for equipment subjected to dynamic excitations, such as seismic studies.

We handle a variety of stresses, such as climatic loads (snow and wind), seismic loads, pressure loads (internal, external, hydrostatic), forces and torques, and temperature variations.

Our methodical approach and advanced expertise guarantee precise, effective solutions to your industry's most complex challenges.Contactez-nous dès aujourd'hui pour bénéficier de notre expertise et découvrir comment GCER peut optimiser vos projets industriels.