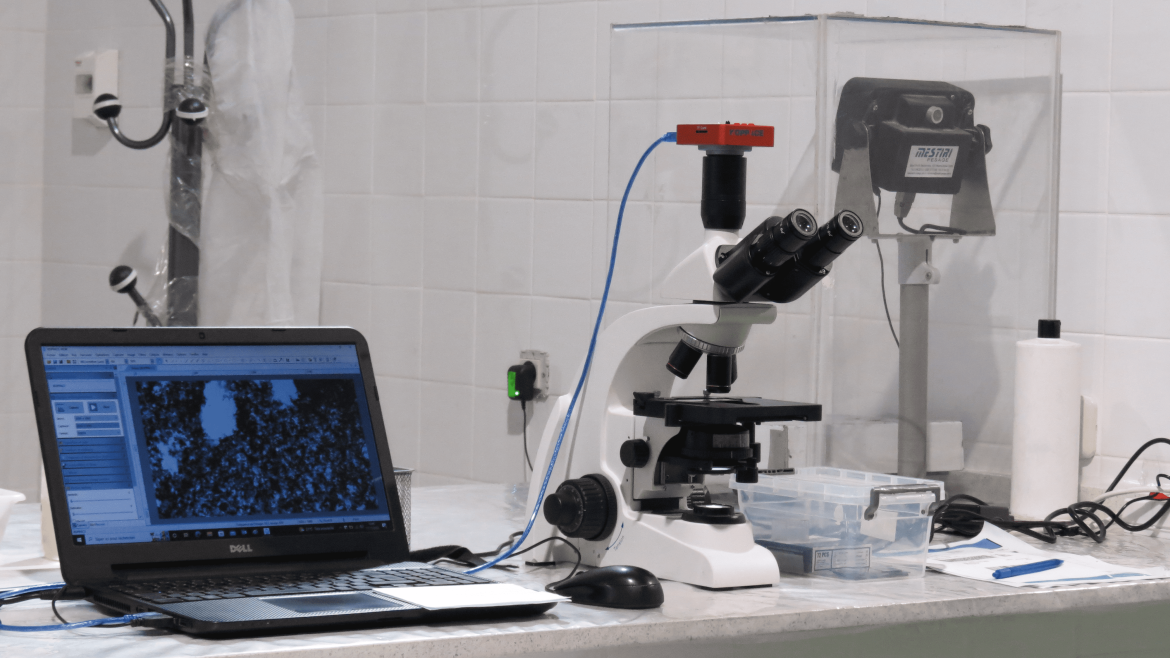

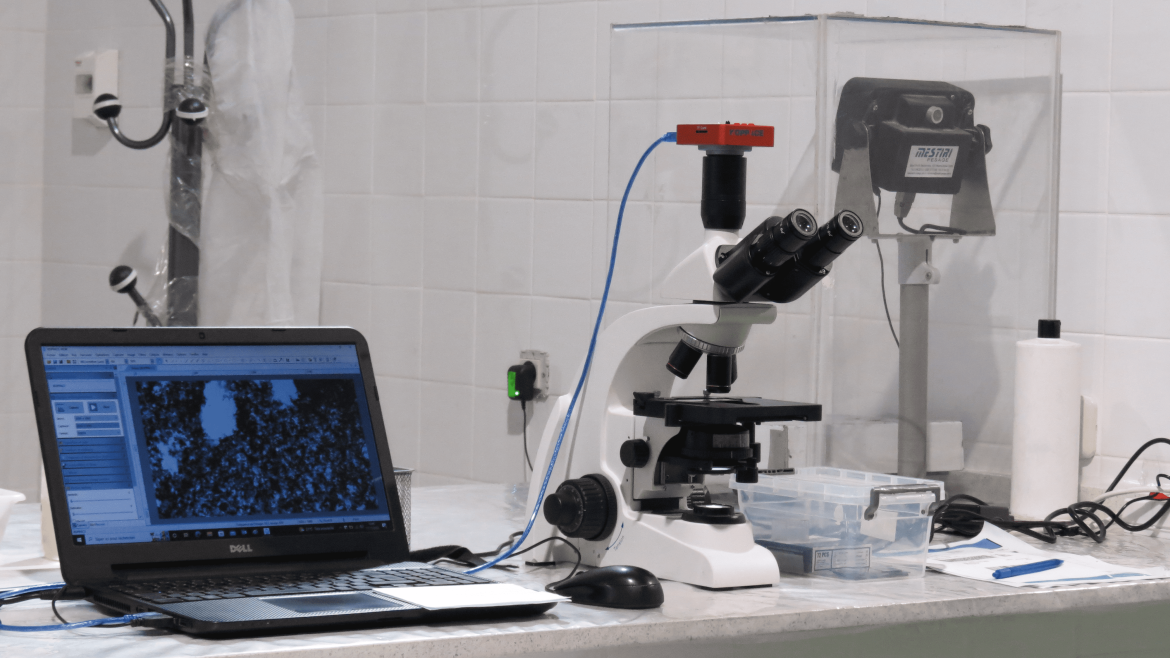

GCER's laboratory carries out a wide range of in-depth tests and trials to ensure the quality of raw materials, mechanical properties, equipment (tanks and boilermaking equipment, etc.), pipes and fittings, as well as long-term product reliability.

These tests can be divided into four main categories :

Since its creation, GCER has relied on its Research and Development (R&D) department to carry out innovative and systematic activities aimed at increasing the body of knowledge and designing new applications based on available knowledge.

Among these R&D activities is the carrying out of several tests and trials on different prototypes in order to verify empirically the research hypotheses, and validate the scientific and technical uncertainties, that the product will have in its final production state.

GCER carries out incoming inspection of the raw materials used in the production of its equipment (tanks, vessels, boilermaking equipment, etc.) pipes and fittings to ensure that they comply with the required specifications.

The raw materials used in the production of pipes and fittings are :

It is compulsory to check the conformity of the receipt with the order, the product identity, the batch number and the comparative verification of the analysis bulletin corresponding to the batch delivered with the product specifications and the typical results obtained on the data sheets and previous deliveries.

Traceability of raw materials through the production process is essential. All records specific to the receipt of each raw material (delivery note, technical data sheet, certificate of analysis, safety data sheet) are kept and properly recorded before they enter the production process.

Details of the specific tests applied to essential raw materials are given below :

Resin :

| Tests | Norms |

| Viscosity determination | ASTM D 2196:05 Method A / ISO 2555 |

| Determining reactivity and measuring gel time | ASTM D 3056:05 / ISO 2535 |

| Solid content determination | ASTM D 1644 |

Glass fibers :

| Tests | Norms |

|

Determination of number of TEX and weight per unit area (weight per unit area). Determination of weight per unit area by wettability test. |

ISO 1889:97 ISO 3374:00 ISO 9073-1:89 |

| Humidity determination | ISO 3344:97 |

| Binder content determination | ISO 1887:95 |

Note :

Catalysts and gas pedals are visually inspected for clarity and the absence of grains or crystals, and tested for reactivity. Every new batch of catalyst or gas pedal must be tested and compared with the previous batch, in the same resin.

Seals made of EPDM, NBR or NEOPRENE, etc... They are visually inspected for weight, hardness and dimensions. All seals must be free of defects or irregularities that could affect their function.

The laboratory team carries out various tests to characterize the mechanical properties of the materials used at GCER.

|

Tests |

Description |

Norms |

|

Standard traction |

Determination of modulus of elasticity in MPa Determination of stress at break in MPa Determination of maximum elongation in %. |

ISO 527& ASTM 638 |

|

3-point bending |

Determination of deflection at break in mm Determination of modulus of elasticity in MPa Determination of flexural strength in MPa |

ASTM D790, EN ISO 14125 |

|

Interlaminar tensile shear |

Determination of apparent shear stress in MPa |

EN 13121-3, BS 4994 |

|

Interlaminar flexural shear |

Determination of apparent shear stress in MPa |

EN 14130 |

|

Determination of apparent initial circumferential tensile strength. Circumferential tension. |

Determination of modulus of elasticity in MPa Determination of stress at break in MPa Determination of maximum elongation in %. |

EN 1394, ASTM D 2290 |

|

Determination of strength Apparent initial longitudinal tension. Longitudinal tension. |

Determination of modulus of elasticity in MPa Determination of stress at break in MPa Determination of maximum elongation in %. |

ASTM D 2105 ISO 8513 EN 1393 |

|

Peel strength of laminate interlayer adhesion |

Determination of maximum peel strength in N/mm |

EN 13121-3 & BS 4994 |

|

Initial specific annular stiffness and initial |

Determination of initial specific ring stiffness (SO) in N/m² Determination of specific relative annular stiffness before internal cracking Determination of specific relative annular stiffness resistance before structural failure Determination of stiffness factor (SF) in Pa.m^3 |

EN 1228, EN 1226, ASTM D 2412 ISO 7685 |

|

Glass content |

Determination of the filler and glass fibre content of the material in %. |

EN ISO 1172, NFT 57-518, ASTM D 2584 |

|

Barcol hardness |

Determination of HB hardness |

NF EN 59, ASTM D 2583 |

Manufacturing process control helps maintain production stability.

The quality control team guarantees the reliability of your manufacturing processes. It also provides essential technical support for validating new manufacturing procedures and/or methods.

Manufacturing process control activities are carried out by the quality control department and include :

GCER is committed to setting up a L.O.F.C. (List of Manufacturing and Control Operations). This will enable us to monitor and manage all the control phases specific to each project, from procurement through to delivery of the equipment.

At the end of the project, these various controls will enable us to submit a manufacturer's file including :

It is also important to point out that, with our own laboratory, we can carry out ovalization, bending, tensile and pressure tests, etc., using our own resources.

Approvals :

All our Qualifications of Operating Mode and Stratification (QMOS) as well as our MTP laminators and welders are qualified according to the following standards and codes:

Approved by a recognized inspection body (APAVE).