Pioneer in Composite Materials and Technological Innovation

GCER started out with a team of engineers and technicians dedicated to finding innovative solutions. From the outset, the company has distinguished itself by specializing in the study, design and manufacture of GRP (Glass Reinforced Plastics) and thermoplastic piping and boiler-making. This strategic orientation has enabled GCER to become a recognized leader in its field, offering reliable solutions tailored to the complex requirements of its customers.

GCER has preserved its pioneering spirit, placing particular emphasis on human and technological values. The company continually invests in the training of its personnel to maintain a high level of competence and meet the challenges of the market.

Summary of our evolution

For over 20 years, we have been committed to excellence and innovation, shaping GCER's path to become an undisputed leader in our field. Here's an overview of our evolution over the years :

-

Founding of GCER SA

In 2001, GCER SA was founded by Mr. Mohamed Bouassida in Ksibet Sousse. The company covers an area of 3 hectares, including 15,000 m² of specialized workshops. More than 200 employees are dedicated to the design of piping and boiler-making systems.

-

Certification and expansion

On May 23, 2005, GCER reached a crucial milestone by obtaining ISO 9001:2000 certification for its design and manufacture of thermoset and thermoplastic (SVR and MTP/F) boiler-making and piping systems. This certification has played a key role in enabling GCER to diversify its product range, notably with the manufacture of SVR tanks, supporting our continued growth in the market.

-

International expansion with AQUATECH-GCER

In 2007, GCER expanded its international presence by creating AQUATECH-GCER, our subsidiary dedicated to better serving Spanish customers and strengthening our presence in the Canary Islands as well as in Latin America, notably Peru and Chile.

-

Continuous Commitment to Quality

In 2008, GCER renewed its quality management system, confirming our continuous commitment to operational excellence and customer satisfaction.

-

Expansion and investment

In 2009, GCER strengthened its financial base by increasing its share capital to €2,050,000, enabling us to support our growth and future ambitions in the field of composite materials.

-

Transition to Excellence

In 2010, GCER finalized its transition to ISO 9001:2008, initiated on July 30, reinforcing our quality management practices and our commitment to continuous improvement.

-

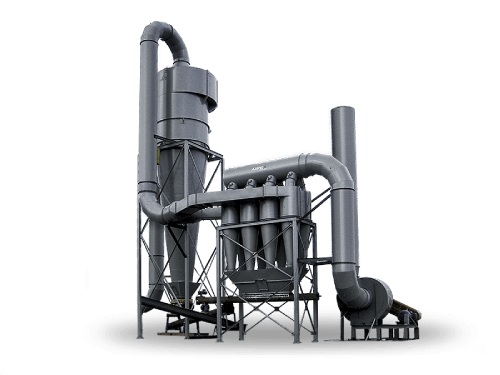

Innovation and Reinforced Quality Norms

In 2011, GCER took significant steps to improve the environment in its workshops by installing decompression cyclones, reducing dust generation by up to 85%. A volatile organic compound (VOC) recovery system was also implemented to optimize air quality during the filament winding process. At the same time, our commitment to quality was underlined by the renewal of ISO 9001:2008 certification on May 23, 2011.

-

Certification and Commitmen

In 2013, GCER achieved ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007 certification for our integrated QSE management system. We also expanded our facilities to support our continued growth and reinforce our advanced environmental management practices.

-

Expansion and Innovation

During this period, GCER strengthened its capabilities by investing in state-of-the-art equipment for its boiler-making workshop. The introduction of technologies such as digital cutting, welding robots and polyfusion machines for thermoplastics enabled GCER to improve its production and offer high-quality GRP solutions. We have also extended our product range with the development of innovative rotating flanges and brackets, consolidating our market position.

-

Geographic expansion and renewed certification

In 2017, GCER made progress by building a new workshop for GRP (Glass Reinforced Plastics) cartridge filters and investing in machinery for grating production. At the same time, we renewed our triple Quality, Safety and Environment certification, demonstrating our commitment to high standards in all our operations.

-

Innovation and structured growth

In 2018, GCER consolidated its position by introducing new workshops for the manufacture of large-diameter tanks and boiler-made appliances, responding to growing demand for large-scale equipment. Our investments in advanced technologies, such as VOC dust extraction at source, have strengthened our ability to offer innovative and sustainable solutions to our customers.

-

Facility Expansion and MSI 20000 Certification

In 2019, GCER expanded its facilities with the addition of new hangars to support the company's continued growth. Achieving MSI 20000 certification underlined our commitment to continuous process and performance improvement. We also strengthened our operational capabilities with the introduction of ERMAKSAN cutting machines and the installation of additional overhead cranes, reinforcing our ability to meet our customers' needs.

-

Adaptation and growth despite challenges

In 2020, despite the challenges posed by the COVID-19 pandemic, GCER maintained its dynamism by taking proactive measures such as automating operations and acquiring new equipment to improve efficiency and productivity. We have built a new hangar and invested in machinery such as saws, welders and CNC machines, boosting our production capacity to respond effectively to market needs.

-

Expansion and reinforcement of production capacity

In 2021, GCER continued to grow by expanding its facilities, notably with the construction of a new grating workshop and the enlargement of the existing laboratory to maintain high quality standards. We strengthened our production capacities with the acquisition of additional filament winding and CNC machines, consolidating our market leadership.

-

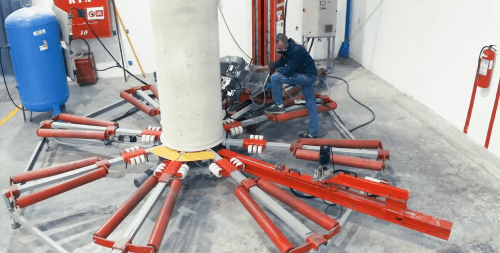

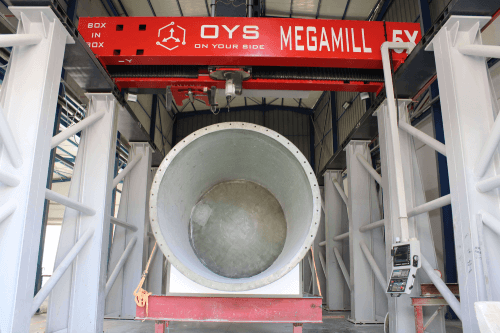

Investment in state-of-the-art technology and AEO certification

In 2022, GCER has acquired new state-of-the-art equipment, including a MEGA 5-axis robot, a steel drilling machine, an M 1400 double-shaft mill, overhead cranes and a hydraulic CNC machine. These investments testify to our ongoing commitment to remaining at the cutting edge of technology, in order to offer our customers innovative, high-quality solutions. In addition, we have been awarded the Label of the Economic Operator Approved by Tunisian Customs and the World Customs Organization, consolidating our position on the international market.

-

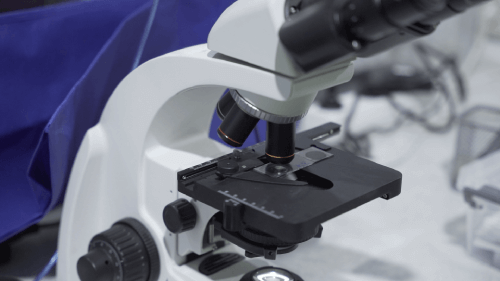

New Analytical Chemistry Research Unit

In 2023, GCER opened a new analytical chemistry research unit for the development of advanced conductive composites, including the use of carbon nanotubes. We invested in state-of-the-art equipment such as electrical resistance measuring instruments, an advanced digital microscope with integrated software, and a high-precision densimeter.